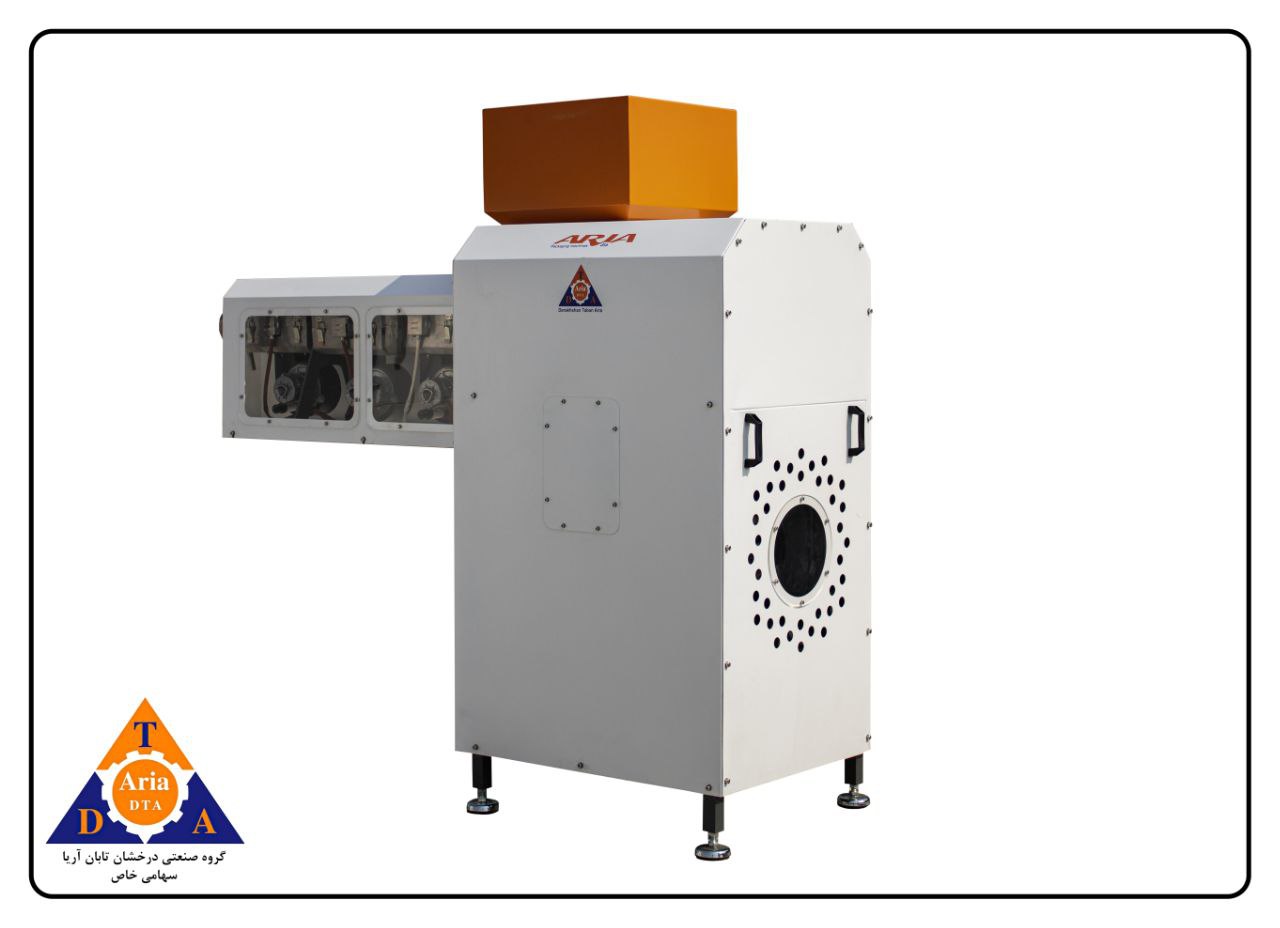

Extrude machine for producing polymer pipes (polyethylene)

Extrude machine for producing polymer pipes (polyethylene)

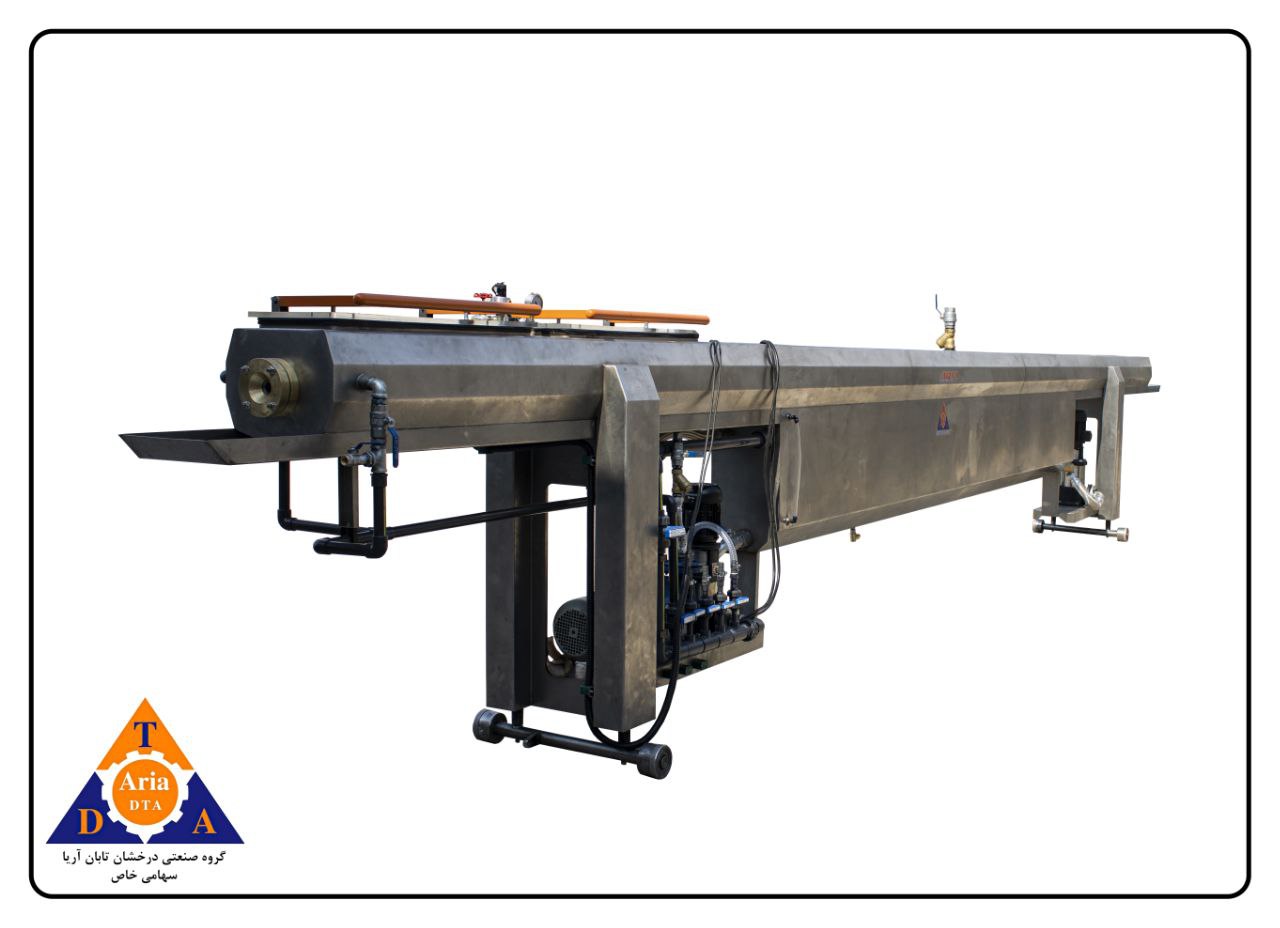

The production process of polymer pipes is by extrusion method and they are widely used in polymer industries with various applications. In the extrusion process, the raw material is fed into the extruder in the form of granules, then the melted material is passed through the mold by Mardon with pressure and produces a product with a specific cross-section shape, then it enters the calibrator. whose task is to accurately adjust the dimensions and shape of the pipe. The vacuum pressure system is used to adjust the dimensions in the calibrator. The calibrator is installed inside the vacuum tank, and the tube inside the vacuum tank is cooled by water to maintain its original shape.

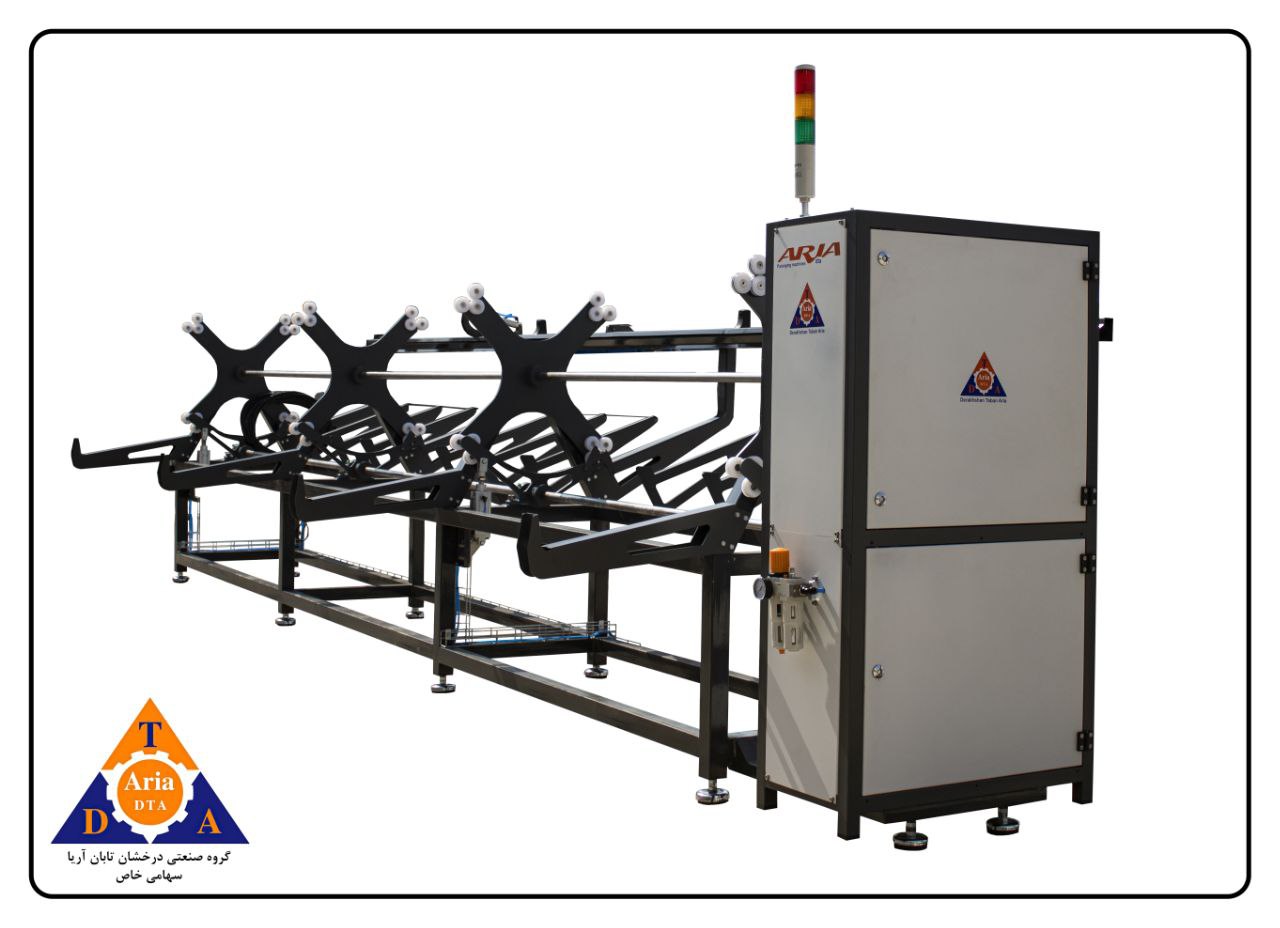

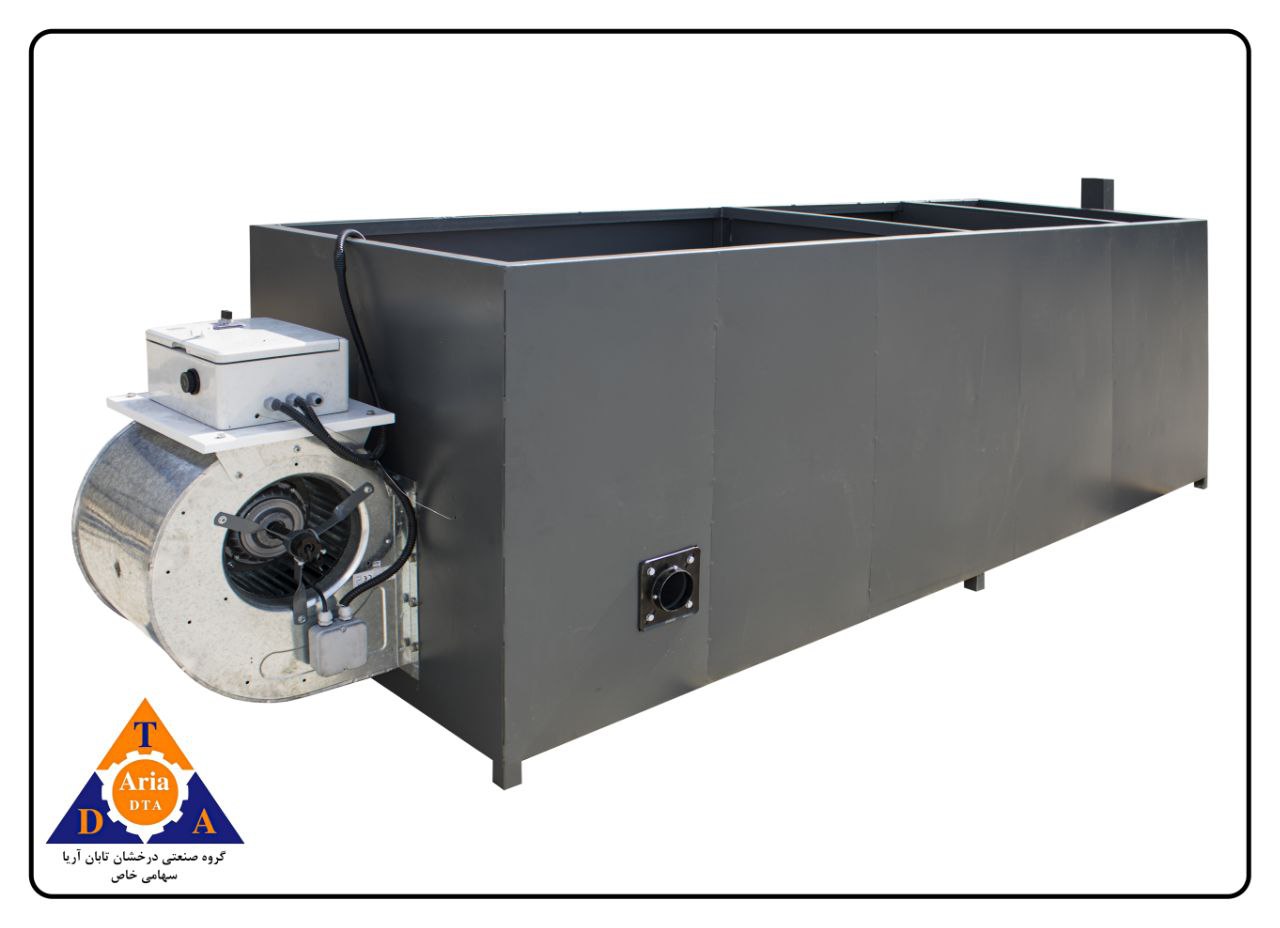

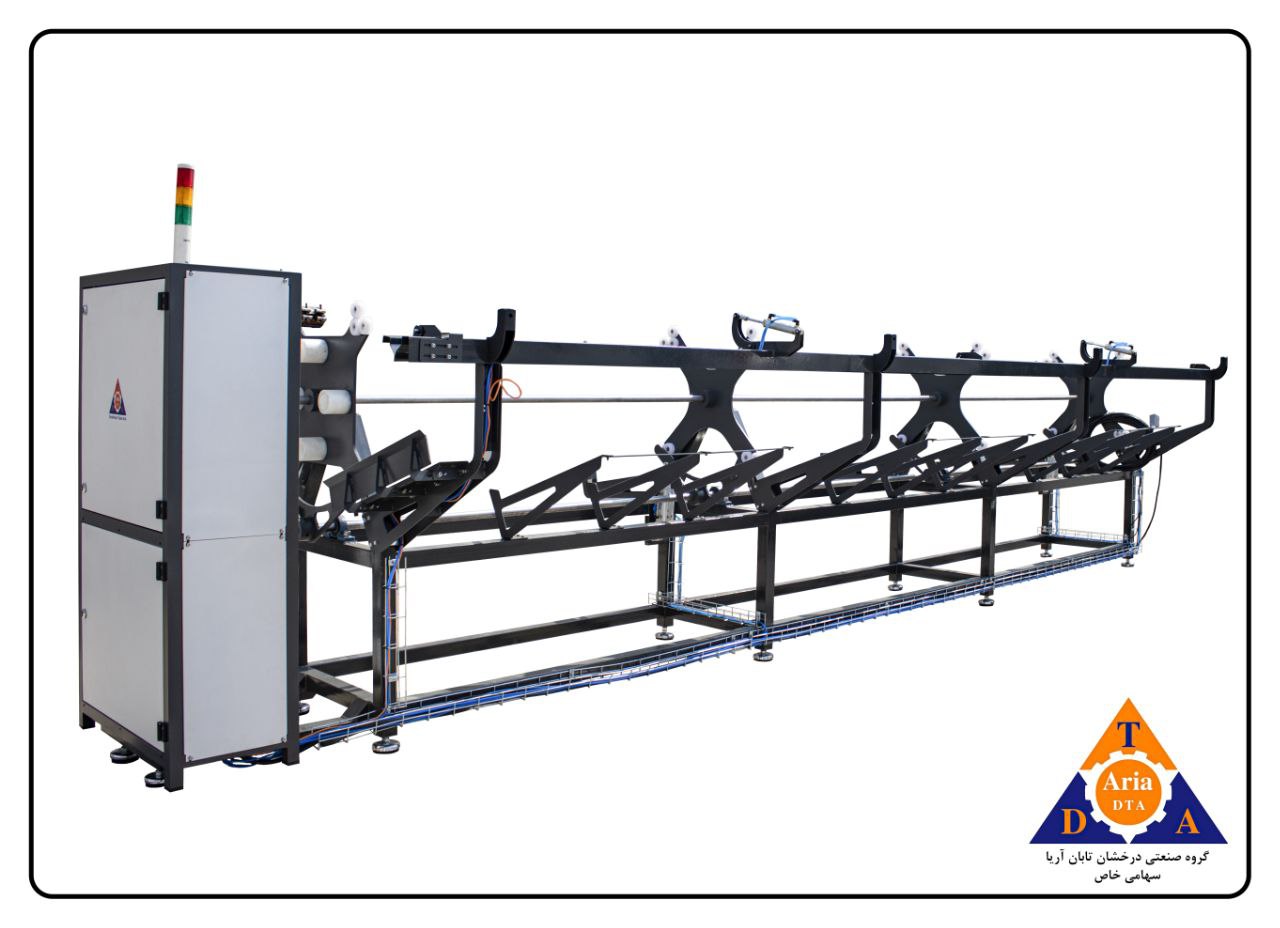

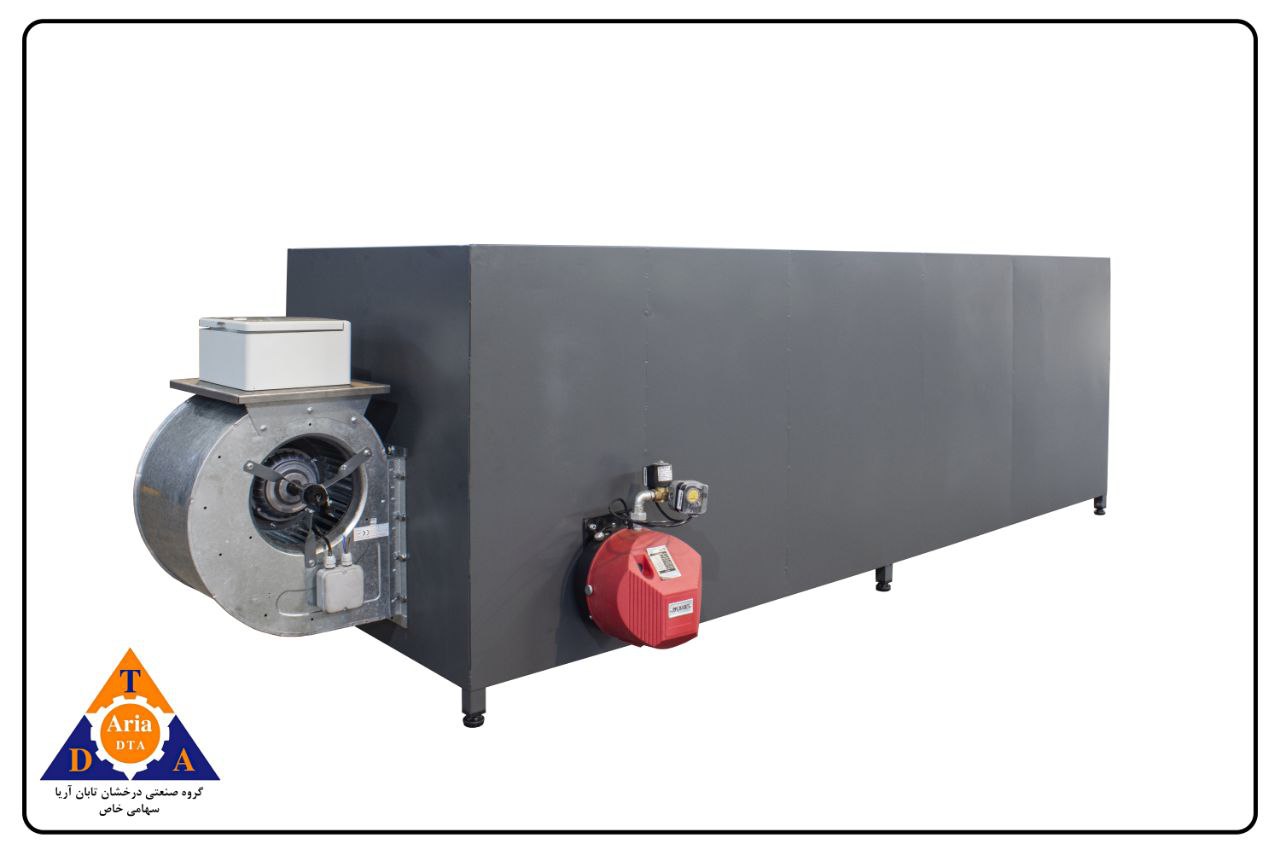

In the cooling stage, the heat of the tube that is left at the output of the calibrator stage is lost. This process is done by two methods of spraying or immersion, each of which has its own advantages and uses. Directing the final product to the packaging section is done by the pulling section.

It is reminded that you, dear customer, can add the following options to order this device:

• Automatic cutter with the ability to adjust the desired size

• Fully automatic bushing section

• Automatic roll collecting section for rolling pipes that are produced in long lengths (50 to 100).