Vacuum conveyor device

Vacuum conveyor device

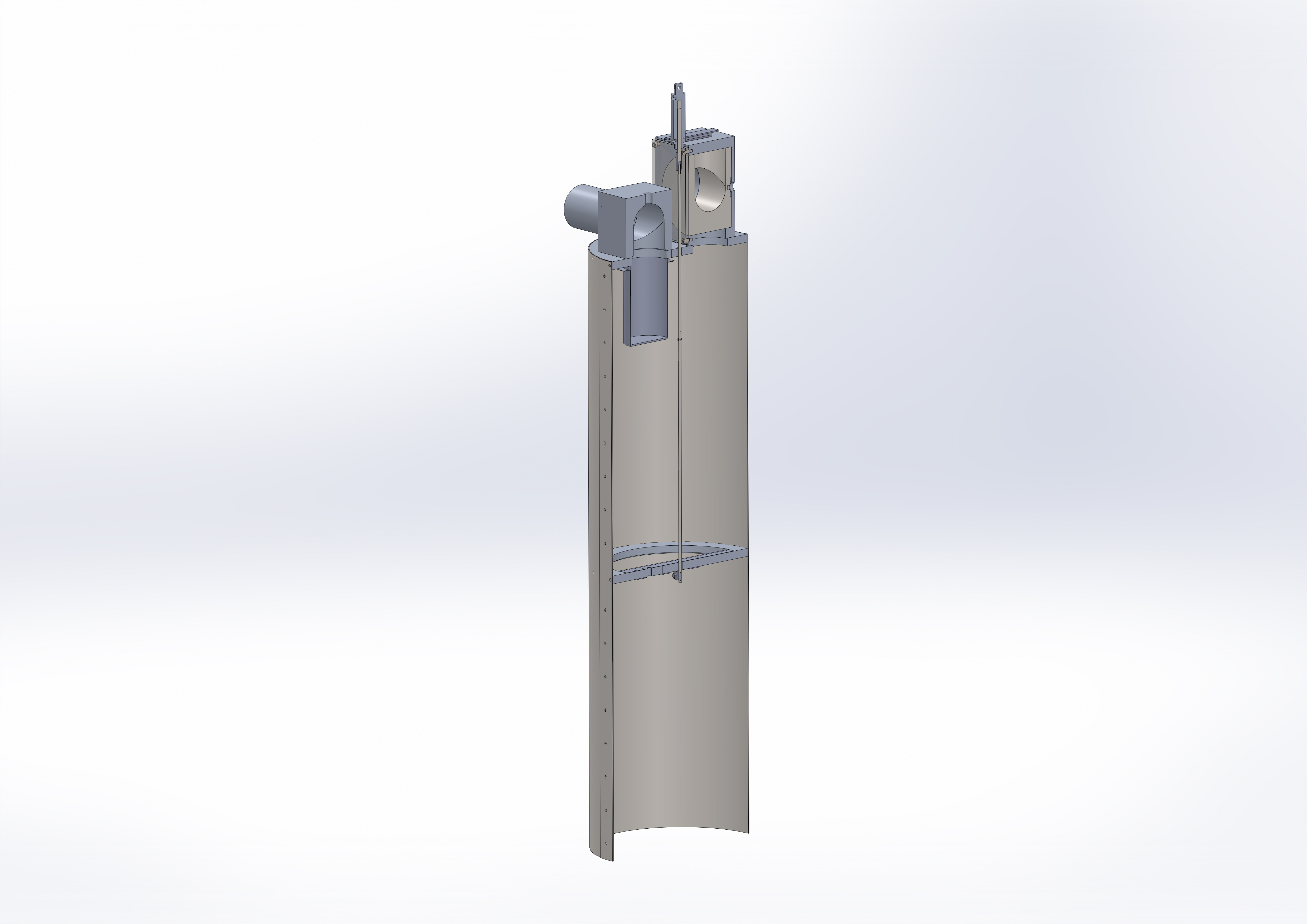

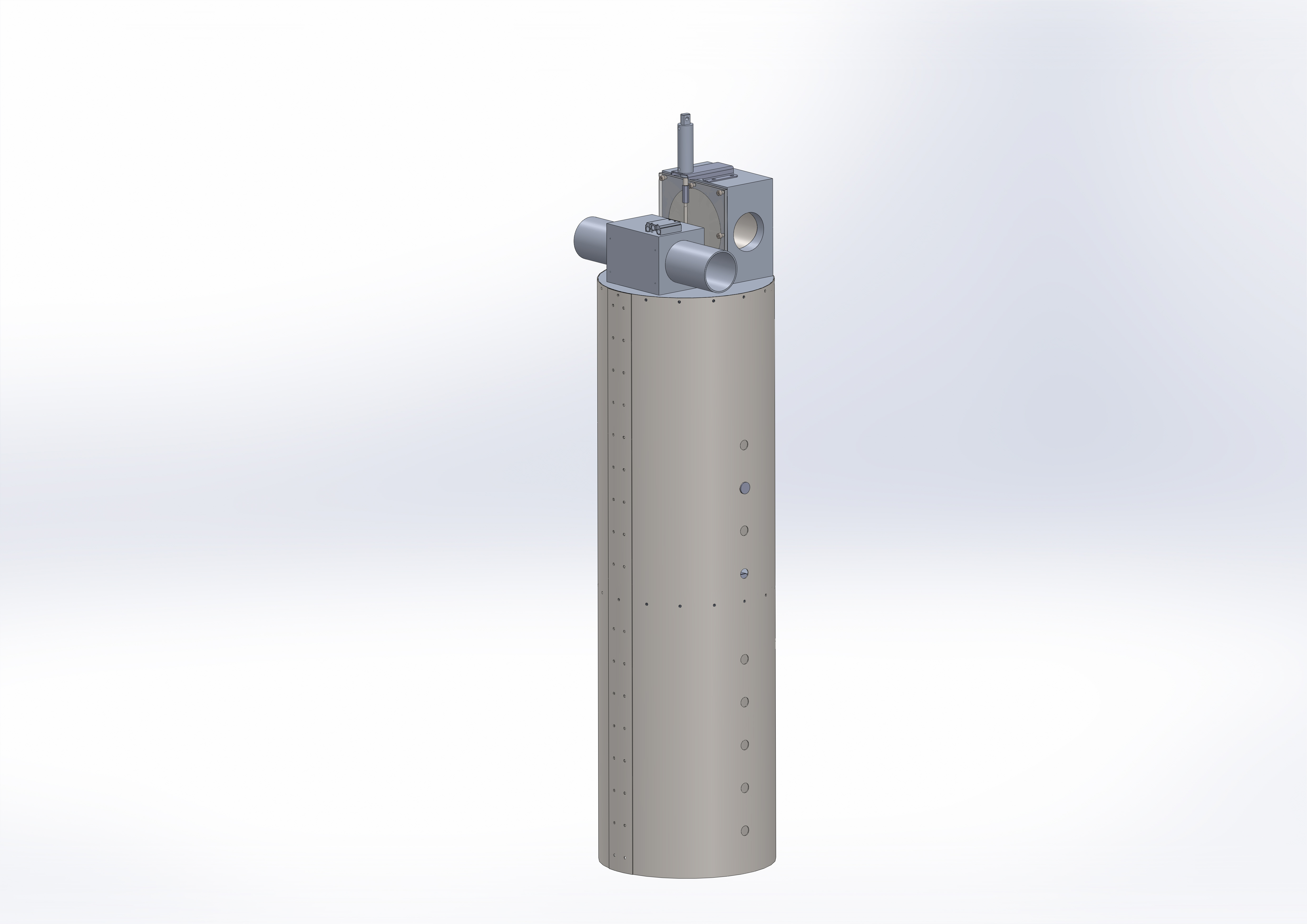

Material transfer in this technology is done by suction and vacuum method. In fact, the air is sucked through the tube and the atmospheric pressure moves the air into the suction tube, at this time the air flow formed under the atmospheric pressure directs the solid materials into the suction tube.

The materials are transferred from the feeding point to a chamber through a pipe. At this stage, the air must be separated from the materials. Therefore, in this place, special filters separate and clean the air from the materials to be transported before it enters the pump. This entire operation is controlled by a programmed control system. It should be noted that even if a leak occurs in the system, the materials will not leak to the outside environment, because the system uses a vacuum mechanism.

The scope of application of vacuum conveyors is to transfer powder, particles, pigments, granular materials, tablets, capsules, etc. from one place to another without height restrictions in two points

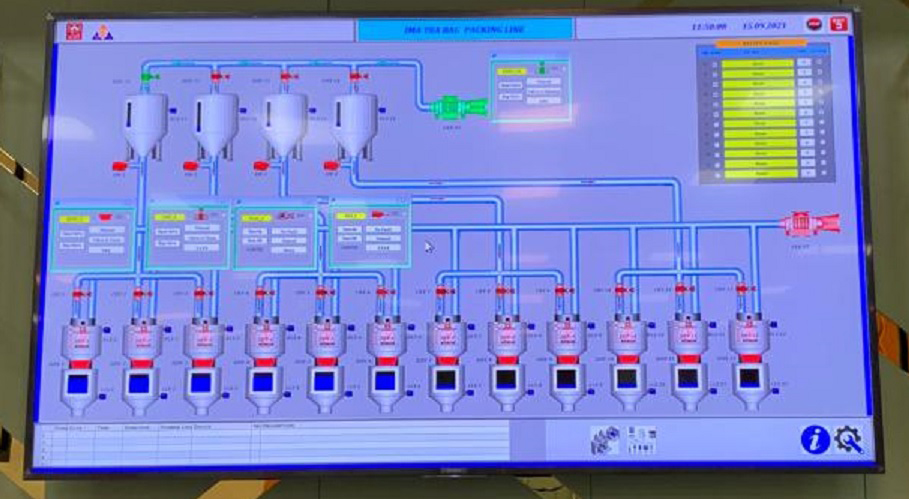

Special features of the product:

Transporting materials free of dust and environmental pollution - System with very high efficiency and low weight - Very few maintenance repairs - Minimal corrosion, erosion and wear in the entire process - Very easy to install and control the process - The ability to supply materials from one to 12 points Simultaneously - Replenishment of feeding points automatically and according to the set schedule - Reduction of human error during product transfer to different points - Ability to connect to several points with different products and move all products at the same time - Other conveyor devices can transfer materials transfer from one point to another, but the advantage of this device is to transfer materials from several selectable points to several other selectable points. - All controls are performed by the ultra-advanced PLC program and all steps and routes are schematically displayed and controlled on the device monitor.